There was a time when confidence seemed tied to appearance alone. Women were told to ...

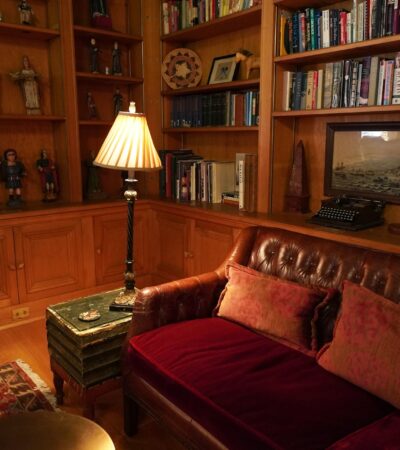

Home remodeling projects provide ideal opportunities for reconsidering organization and storage approaches. While most property owners prioritize visual appeal and functionality, integrating effective storage solutions can transform a disorganized space into a structured, efficient area that enhances your daily life. These storage approaches help optimize spatial utilization while maintaining orderly, ...

Is your bedroom helping you sleep or secretly sabotaging it? Most people underestimate how much ...

Sometimes, it’s the small stuff that ends up costing the most. Not just in money, ...

Choosing a tattoo is not just about the design. It’s about what that design represents, ...

If your work or environment requires personal protective equipment, and you wear glasses, then regular ...

Planning a birthday party for a shy child requires special consideration and thoughtful preparation. While ...

About Us

Hello!! Welcome to Sneaky Mommies

Sneaky Mommies is a vibrant lifestyle platform that celebrates the art of modern living. It offers inspiration and ideas for parenting, home decor, food, and travel,